Trace Tech No-Clean Flux Dispensing Pen, 10.5ml

Resin and halide-free no-clean flux has excellent wetting abilities and leaves no problematic residues. Excellent for prototyping, rework, and repair and to provide extra wetting for lead-free wire solder.

- Excellent wetting

- Works with lead and lead-free solders

- No cleaning necessary

- Boost wetting for lead-free wire solder

- Non-ozone depleting

- Comprar 12 por USD 9.94 cada uno

- Comprar 50 por USD 9.83 cada uno

- Comprar 100 por USD 9.73 cada uno

FAQs

What flux should I use when replacing PCB components?

TraceTech No-clean Flux Pen is formulated to perform at the elevated temperatures of lead-free soldering but is also effective for tin-lead soldering as well. It's designed with a low surface tension to prevent bridging. Post-soldering cleaning is optional because the light residue left after soldering is barely noticeable is non-corrosive and halide free. Flux pens are an excellent way to dispense flux for benchtop soldering. You just hold the pen vertically and briefly depress the tip to start the liquid flow. This will saturate the tip of the pen with flux. Draw flux on the area to be soldered. Gently press the tip again when more flux is needed to keep the tip damp with flux.

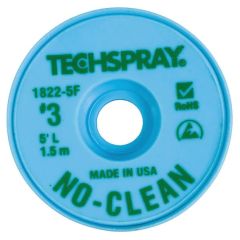

Can I add my own flux to solder wick?

In a production or repair environment where the flux is specified and can’t be changed, or when an aqueous flux is needed, you can add your own flux to this type of braid. Unfluxed wick will not remove solder unless flux is added. TraceTech No-Clean Flux Pen is formulated to perform at the elevated temperatures of lead-free soldering but is also effective for tin-lead soldering as well. It's designed with a low surface tension to prevent bridging. Post-soldering cleaning is optional because the light residue left after soldering is barely noticeable and is non-corrosive and halide free. This is a good choice for tin-lead soldering where cleaning is to be avoided.

How do I figure out the shelf life of a product?

The shelf life of a product can be found on either the technical data sheet (TDS), available on the product page, or by looking on the certificate on conformance (COC). Once you have the shelf life, you will need to add it to the manufacture date for a use-by date. The manufacture date can be identified by the batch number. The batch code used on most of our products are manufacture dates in the Julian Date format. The format is YYDDD, where YY = year, DDD = day. For example, 19200 translates to the 200th day of 2019, or July 19, 2019.

*This item is hazardous and will be subject to an additional Hazmat fee

| SKU | I173556 |

|---|---|

| Modelo del fabricante | 2507-N |

| Marca | TechSpray |

| Tipo | Dispensador de soldadura/Fundente |

| Talla/Tamaño | 10,5ml |